Maintenance Tips for Asphalt Pavements in Overland Park

Introduction

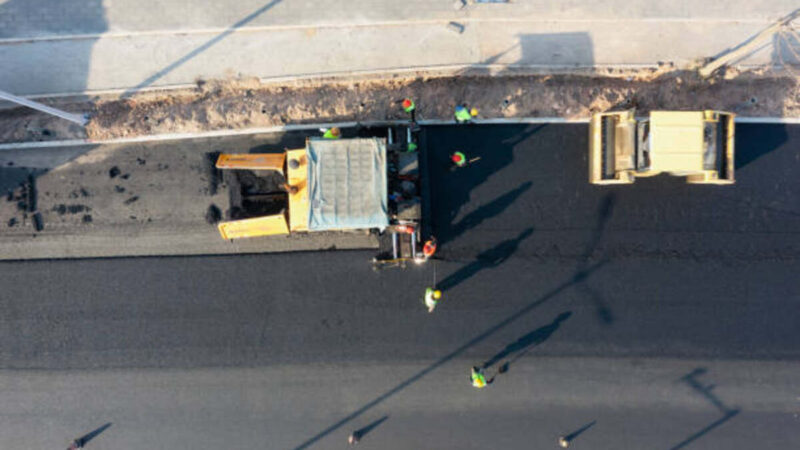

Maintaining asphalt pavements is more than just a routine chore; it’s a smart investment that protects property values and ensures safe travel for everyone. In Overland Park, where fluctuating weather conditions and heavy traffic can take a toll on roads, following the right maintenance tips can extend the life of your asphalt surfaces considerably. Maintenance Tips for Asphalt Pavements in Overland Park should be part of every property owner’s or municipality’s regular checklist. From the moment you lay the first layer of asphalt to the regular upkeep needed to keep it in excellent condition, proper maintenance is key to avoiding expensive repairs and unexpected hazards. Have the Best information about Asphalt Overland Park.

Asphalt is a durable yet perishable material, and if you neglect its upkeep, small issues can quickly escalate into major problems. This article delves into an in-depth look at how to care for asphalt pavements, offering a step-by-step guide and actionable advice. We’ll discuss why Overland Park demands particular attention, share essential maintenance practices, explore advanced strategies to prolong pavement longevity, and provide a robust framework for implementation and monitoring. Whether you’re a local homeowner, a facility manager, or a city planner, the insights presented here are designed to empower you with the knowledge needed to make informed decisions about asphalt care.

The importance of addressing routine maintenance cannot be overstated. When you catch issues early, like minor cracks or drainage problems, you’re able to tackle them quickly before they develop into safety hazards or lead to significant financial setbacks. Moreover, regular upkeep not only improves safety but also enhances the overall aesthetic appeal and functionality of your property. This guide emphasizes the role of periodic inspections, timely repairs, and the application of protective measures that can mitigate the adverse effects of environmental stressors such as UV rays, precipitation, and temperature variations.

In Overland Park, the local climate presents unique challenges. The region experiences a mix of hot summers and cold winters, which causes the asphalt to expand and contract. These temperature fluctuations can lead to surface cracks and eventually create potholes if not addressed promptly. Additionally, heavy rains may contribute to poor drainage, further accelerating the deterioration of the pavement. Thus, incorporating local climate considerations into your maintenance plan is vital. Not only does this proactive approach help in sustaining the pavement’s durability, but it also ensures a safer and smoother ride for motorists.

Another critical factor in effective pavement management is understanding that maintenance is not a one-size-fits-all process. It requires a combination of routine inspections, preventive treatments, and, when necessary, more in-depth repairs. For instance, crack sealing is a cost-effective measure that prevents water from seeping into the underlying layers, thereby reducing the risk of more extensive damage. Similarly, applying sealcoats can provide a protective layer against harmful elements and extend the life of your asphalt surface. This comprehensive approach is what makes a maintenance plan truly successful.

Moreover, educating yourself about the latest advancements in asphalt technology and maintenance practices can pay dividends in the long run. Innovations in materials and application methods have made it easier to perform maintenance with minimal disruption. By staying up-to-date with these developments, you can implement strategies that not only save money but also improve the overall efficiency of your pavement maintenance program.

Throughout this article, you’ll find that we break down the maintenance process into manageable sections, each filled with practical tips and real-life examples. Our goal is to offer you a detailed yet easy-to-follow guide that meets a Grade 7 reading level while still being rich in expert advice. We use contractions and colloquialisms to keep the tone friendly and relatable, ensuring that even complex topics are accessible. So, let’s dive into the world of asphalt maintenance, and discover how you can transform routine upkeep into a robust plan that stands the test of time.

In the sections that follow, we’ll start by outlining the essential maintenance practices that form the backbone of any effective strategy. We’ll then explore advanced techniques that leverage the latest in asphalt technology, followed by a detailed look at implementation and monitoring. By the end, you’ll be armed with a wealth of information to keep your pavements in prime condition, ensuring safety and longevity for years to come.

Essential Maintenance Practices

Maintaining high-quality asphalt surfaces requires a proactive and systematic approach. In this section, we detail the core practices that ensure your pavement remains in excellent condition for an extended period. These practices, when carried out consistently, not only prevent deterioration but also add significant value to your property.

Regular Inspections and Early Problem Detection

Routine inspections are the cornerstone of effective pavement maintenance. It’s best to inspect your asphalt surfaces at least twice a year—once before the harsh winter months and once in the spring. Early detection of issues like minor cracks, discoloration, or potholes can help you address problems before they worsen. Regular checks allow you to spot wear and tear early and schedule timely repairs, thus preventing more significant damage.

Here’s a quick checklist for your inspection routine:

- Surface Cracks: Look for any small cracks that could become larger over time.

- Discoloration: Check for uneven patches that might signal underlying issues.

- Potholes: Identify any depressions or holes that may have started forming.

- Drainage Issues: Ensure that water isn’t pooling on the surface.

- Edge Deterioration: Examine the borders of the pavement for signs of erosion.

Using a flashlight on a sunny day can help you notice fine cracks that might be missed during daylight. Always document your findings with photographs and notes to track the progress of any issues. Early detection is not only more cost-effective but also prevents safety hazards that could result in accidents.

Crack Sealing & Pothole Repairs

Crack sealing is one of the most critical tasks in pavement maintenance. When left unattended, small cracks allow water to infiltrate the underlying base, eventually leading to potholes and even structural failure. Sealants are designed to prevent water intrusion and keep the pavement flexible. It’s advisable to seal cracks as soon as they appear, ideally during dry weather, to ensure the sealant bonds properly.

Pothole repairs, on the other hand, are slightly more involved. Once a pothole develops, it must be filled promptly to prevent it from expanding. The repair process typically involves cleaning out the damaged area, applying a suitable patching material, and then compacting it to match the surrounding surface. Regular maintenance routines that include both crack sealing and pothole repairs can significantly extend the life of your asphalt.

Surface Treatments & Sealcoating

Sealcoating provides a protective barrier that shields your asphalt from the elements. Over time, the sun’s UV rays, rain, and oil spills can wear away the surface. By applying a sealcoat every few years, you create an additional layer of defense against these harmful agents. Sealcoating not only enhances the appearance of the pavement but also helps to slow down oxidation and degradation.

To make the most of sealcoating:

- Clean Thoroughly: Ensure that the pavement is clean and dry before application.

- Choose the Right Product: Select a sealcoat that suits your climate and traffic conditions.

- Apply Evenly: Use professional equipment to achieve a uniform layer.

- Follow Up: Regularly inspect the sealcoated surface for signs of wear and reapply as needed.

A well-sealed surface can improve the overall durability of the pavement and reduce the frequency of more intensive repairs.

Drainage & Site Management

Poor drainage is a major enemy of asphalt. When water lingers on the pavement, it can seep into cracks, causing further deterioration. Effective site management involves ensuring that water is directed away from the pavement. This may include grading the site properly, installing drainage channels, or using permeable materials in adjacent areas to absorb excess water.

Consider this simple table that compares different drainage solutions:

| Maintenance Task | Frequency | Benefits | Cost Considerations |

| Routine Drainage Check | Biannually | Prevents water accumulation | Minimal inspection costs |

| Installing Drainage Channels | As needed | Directs water away from the pavement | Moderate initial investment |

| Surface Grading | Every 3-5 years | Ensures proper slope for water runoff | Higher cost but long-term benefits |

Combining these drainage solutions with regular maintenance ensures that water is efficiently managed, thereby reducing the risk of water-related damage. Good drainage practices are essential, especially in areas like Overland Park, where sudden rainstorms can quickly affect pavement quality.

Overall, incorporating these essential maintenance practices into your routine can help you avoid costly repairs and extend the lifespan of your asphalt pavements. By keeping a vigilant eye on your surfaces and addressing issues as soon as they arise, you can ensure that your pavement remains durable and safe for years to come.

Advanced Strategies for Longevity

While basic maintenance practices form the backbone of asphalt care, leveraging advanced strategies can elevate your approach and yield even better results. In this section, we explore innovative techniques, material selections, and modern technologies that have revolutionized asphalt maintenance. These strategies not only help in addressing current issues but also prevent future problems from emerging.

Material Selection & Techniques

Selecting the right materials is pivotal to achieving a long-lasting pavement. Advances in asphalt technology have introduced a range of modified binders and additives that enhance durability. For instance, polymer-modified asphalts can significantly reduce the risk of cracking in extreme temperature conditions. When planning maintenance, it’s essential to consider the specific demands of your region. For Overland Park, materials that can withstand temperature fluctuations and heavy traffic loads are ideal.

Implementing advanced techniques such as full-depth reclamation and asphalt recycling can also be highly effective. These methods allow you to rejuvenate the existing pavement by removing the surface layer, mixing it with new materials, and laying it down again. Not only does this approach save money, but it also minimizes environmental impact by reusing materials.

Climate-Specific Solutions

Overland Park’s weather patterns present unique challenges. Hot summers combined with cold winters mean that your pavement is subjected to constant stress. To combat these issues, tailored maintenance strategies are crucial. For example, applying sealcoats during the cooler months can ensure better adhesion and longevity, while during the summer, regular inspections help catch any signs of heat-related damage early on.

In addition, incorporating moisture-resistant additives in your asphalt mix can greatly improve its performance during wet conditions. These additives help prevent water from seeping into the pavement layers, thus reducing the likelihood of cracks and potholes. Using climate-specific solutions, you can create a maintenance plan that addresses the particular challenges of your local environment, ensuring that your pavement remains resilient throughout the year.

Innovations in Asphalt Technology

The world of asphalt maintenance is evolving, and staying abreast of the latest innovations can give you a significant edge. Modern technologies, such as infrared pavement repair, allow for rapid and precise patching of damaged areas. This method uses infrared heat to reheat the existing asphalt, which then bonds seamlessly with the new material. It’s an efficient and eco-friendly solution that minimizes downtime.

Another groundbreaking development is the use of sensors and monitoring systems that track pavement performance in real-time. These systems can alert you to issues such as temperature variations or unusual stress patterns, allowing for timely intervention. Incorporating such technology into your maintenance program can save you both time and money in the long run.

Cost-Benefit Analysis of Preventive Measures

One of the key advantages of preventive maintenance is the potential for significant cost savings over time. Instead of facing a massive repair bill when severe damage occurs, a regular maintenance schedule helps distribute costs more evenly. Conducting a cost-benefit analysis of your preventive measures can reveal the long-term financial advantages of regular upkeep.

Consider factors such as:

- Repair Costs: Early intervention costs are generally much lower than major repair projects.

- Downtime: Reduced disruptions mean that businesses and local traffic experience fewer interruptions.

- Extended Lifespan: Proactively maintained pavements can last years longer, delaying the need for complete reconstruction.

- Safety Benefits: Investing in regular maintenance reduces the risk of accidents and liability issues.

When you compare the upfront costs of preventive measures with the potential expenses of major repairs, it’s clear that a proactive approach pays off in the long run. Local government bodies and private property owners alike have found that regular maintenance can significantly extend the useful life of asphalt pavements, ensuring safer roadways and more efficient use of resources.

Moreover, many municipalities in Overland Park have adopted innovative financing models to support long-term maintenance projects. These models often involve partnerships with local businesses and community organizations, spreading the cost burden and increasing accountability. By engaging in a comprehensive cost-benefit analysis, you can determine the most cost-effective strategies tailored to your specific situation.

Overall, advanced strategies in asphalt maintenance are about more than just fixing problems—they’re about preventing them. By selecting the right materials, using climate-specific solutions, and taking advantage of the latest technology, you can develop a robust maintenance program that stands up to the test of time. This proactive approach not only keeps your pavement in great condition but also reinforces the overall safety and efficiency of your infrastructure.

Implementation and Monitoring

Putting theory into practice is where your maintenance plan truly comes to life. In this section, we break down a detailed, step-by-step approach to implementing your asphalt maintenance strategy, along with effective monitoring techniques to ensure lasting success.

Step-by-Step Maintenance Implementation

The first step in successful implementation is developing a clear and concise plan. Begin by outlining all the necessary tasks—ranging from regular inspections and crack sealing to more advanced procedures like full-depth reclamation. Prioritize these tasks based on the current condition of your pavement and the seasonal demands of Overland Park. Creating a detailed checklist can be incredibly helpful. Here’s a simple process to follow:

- Assessment: Conduct an initial survey to document the pavement’s current state.

- Planning: Develop a schedule that outlines when each task should be completed.

- Budgeting: Allocate funds for each maintenance task, keeping contingencies in mind.

- Execution: Begin with the highest-priority tasks, such as sealing cracks and addressing drainage issues.

- Review: After each task, review the results and adjust your plan if necessary.

Using digital tools or simple spreadsheets can streamline this process, making it easier to track progress and manage resources effectively.

Scheduling & Monitoring

Once your plan is in motion, consistent monitoring becomes critical. Set up a monitoring schedule that includes regular inspections at predetermined intervals—ideally, monthly or quarterly. This routine check ensures that any emerging issues are caught early. Consider employing modern sensor technologies that offer real-time data on pavement performance. These sensors can provide alerts for temperature changes, stress points, and other indicators that may signal the need for intervention.

For instance, a monitoring schedule might look like this:

- Monthly Visual Inspections: Check for surface damage and water pooling.

- Quarterly Technical Inspections: Use specialized equipment to measure surface integrity.

- Annual Reviews: Conduct a comprehensive review, including cost-benefit analyses of past repairs.

Maintaining detailed logs and photographic records will help you track improvements over time. Regular meetings with your maintenance team or contractors can also ensure that everyone stays on the same page and that adjustments are made as needed.

Contractor Selection & Training

Even the best maintenance plan requires skilled professionals to execute it. When selecting contractors, look for those with a proven track record in asphalt maintenance, particularly in climates similar to Overland Park. Ask for references, check their previous work, and ensure they use modern techniques and equipment. It’s also wise to invest in training for your in-house team. Offering periodic workshops or refresher courses can enhance their skills, ensuring that they’re up-to-date with the latest practices and technologies.

Case Studies & Success Stories

Learning from others’ experiences can be invaluable. In Overland Park, several municipalities and private organizations have successfully implemented comprehensive maintenance programs. These case studies often highlight how proactive measures not only saved money but also improved overall pavement safety and longevity. For example, one local city reported a 30% reduction in repair costs after instituting a rigorous monitoring schedule and regular preventive treatments. Another community saw a dramatic improvement in road safety and reduced vehicle repair claims after addressing drainage issues and using high-quality sealcoating products.

By documenting these success stories and comparing them to your own experiences, you can fine-tune your maintenance strategy over time. Sharing such case studies within your team or community can also build support for proactive maintenance measures, ensuring long-term buy-in and collaboration.

Overall, implementing a robust maintenance plan isn’t just about following a checklist—it’s about creating a culture of proactive care. With clear steps, regular monitoring, skilled professionals, and ongoing learning, you can ensure that your asphalt pavements remain in top shape. Remember, the goal is to prevent problems before they escalate, saving both time and money while keeping roads safe for everyone.

Frequently Asked Questions

What are the key maintenance tips for asphalt pavements in Overland Park?

The key tips include regular inspections, timely crack sealing and pothole repairs, proper sealcoating, effective drainage management, and using climate-specific solutions to tackle local weather challenges.

How often should I inspect my asphalt pavement?

It’s recommended to conduct visual inspections at least twice a year—ideally before winter and during spring—and to perform more detailed technical inspections quarterly or annually.

What are common issues found in asphalt pavements?

Common issues include cracks, potholes, discoloration, water pooling, and edge deterioration. These problems are often caused by weather fluctuations and heavy traffic.

Can sealcoating extend the life of my asphalt?

Yes, sealcoating creates a protective layer that shields the pavement from UV rays, water, and chemicals, thereby extending its lifespan and reducing the need for frequent repairs.

How do weather conditions affect asphalt maintenance in Overland Park?

The hot summers and cold winters in Overland Park cause the asphalt to expand and contract, which can lead to cracks and potholes if not properly maintained. Tailoring maintenance to these conditions is essential.

Where can I find professional services for asphalt maintenance?

You can start by checking reputable industry associations. Local contractors with strong references and proven expertise in regional maintenance are also a great resource.

Conclusion

In conclusion, maintaining high-quality asphalt pavements in Overland Park requires a mix of proactive measures, innovative strategies, and careful monitoring. From regular inspections and timely repairs to leveraging advanced materials and technology, every step is essential to ensure longevity and safety. Whether you’re a property owner, facility manager, or city planner, these comprehensive maintenance tips empower you to extend the lifespan of your asphalt surfaces while keeping repair costs at bay. By adopting a systematic approach and staying informed about the latest trends, you can build a maintenance program that not only meets today’s demands but also anticipates tomorrow’s challenges.

Remember, a well-maintained pavement isn’t just about aesthetics—it’s about safety, efficiency, and long-term savings. So, start implementing these strategies today and enjoy the benefits of smoother, more durable roads for years to come.